EZ Production Monitor Features & benefits

Innovative Unique Features

- Most accurate Productivity and Quality Monitor.

- Great tool to design Lean cells.

- New invention, there is nothing like this Production Monitor on the market.

- Pre-coded Firmware: Employs a powerful PLC and a Marquee but requires no Programming, all firmware/software is built-in and pre-coded.

- Designed for use by non-technical personnel. Extremely simple User Interface.

- 2 Line 10 character tricolor LED message display readable to 100 ft.

- Red, Yellow and Green LEDs allow messages to be color coded.

- Very simple wiring. Universal Power input, 15 wire cable.

- Up to six inputs and two outputs. Dry contacts or proximity sensors.

- Communicates to a Lap top over WiFi up to 50 ft. away.

- Patent pending smart logic to minimize tampering with the monitor and provide the most accurate information on plant productivity and quality.

- Available in four models.

- Real Time Clock and Data Logging for deeper analysis of production operations

EZ Production Monitor Features & Benefits

New invention, there is nothing like this Productivity and Quality Monitor on the market.

EZAutomation is the biggest supplier of LED message displays/Marquees in the market along with its PLC offerings. Many of its customers use these two products in conjunction with each other to build a production monitor. You need an Automation Control Engineer to do the system design and programming, particularly of the PLC. Hundreds of its customers report dramatic improvement in their plant productivity using the EZMarquee and EZPLC or their own preferred PLC. One particular plant in Ohio reported its output to double when this approach was adopted.

EZ Production Monitor has been designed to eliminate the need of any programming. Any non-technical person, a Production supervisor, Production Manager, a Facilities Manager or the Owner of the business can install and use this EZPM with extreme ease. All you have to do is to enter five parameters in a very simple user interface and the EZPM does the rest. It displays actual production vs. goals.

Great tool to deisgn Lean cells

EZPM is particularly suited for Lean Manufacturing cells. It can be used to design the lean cell, step by step and measure the improvement by each step, ultimately resulting productivity improvement of sometimes as much as 10X

Pre-coded Firmware: Employs a powerful PLC and a Marquee but requires no Programming, all firmware/software is built-in and pre-coded.

The EZPM comes pre-programmed with hard-coded logic eliminating the need for any PLC or Marquee programming. No knowledge of PLCs or programming is needed. Normally a Facilities Manager without knowledge of Automation controls can handle it. EZPM comes with a manual with simple wiring instructions.

Designed for use by non-technical personnel. Extremely simple User Interface.

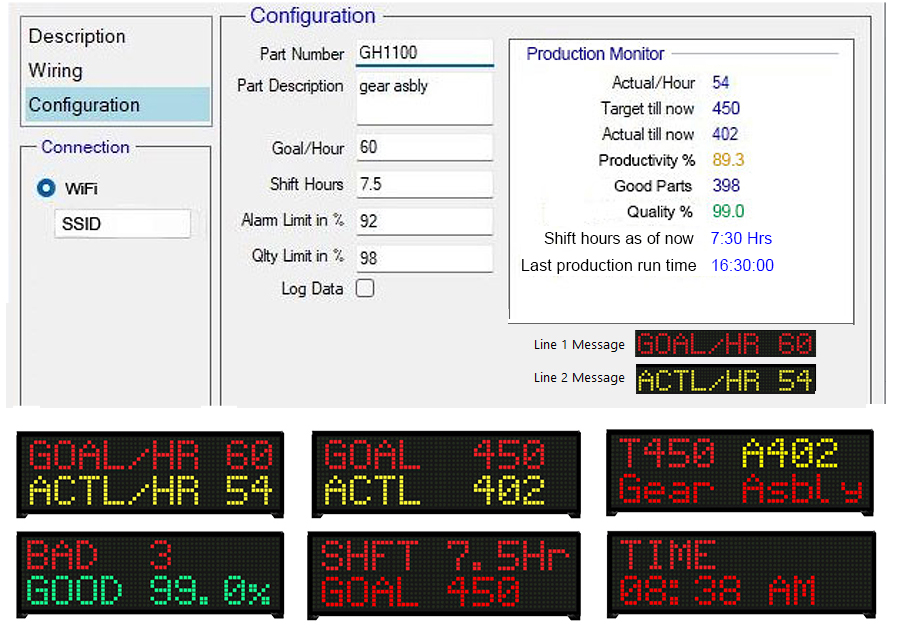

Its User Interface is very simple. All you have to enter on your laptop is: a) Part number b) Shift Hours c) Goal per hour d) Minimum productivity goal e) Minimum Quality Goal and the EZPM does the rest. The Computer connecting to the EZPM also displays how the production line is running, that is the actuals vs. goals. Messages seen on the EZPM can also be shown on the Laptop.

2 Line 10 character tricolor LED message display readable to 100 ft.

The EZPM comes in four models. a) 1 Line 10 Ch Red for $549, b) 2 Line 10 Ch Red for $699, c) 2 Line 10 Ch. Tricolor for $799, d) 2 Line 10 C. Tricolor with Real Time Clock and Data Logging for $899. 2 Inch characters are readable to 100 ft. away. The 1 Line models have a scrolling display to show all the production parameters whereas the 2 Line models have enough characters to show the parameters in stationary messages.

Red, Yellow and Green LEDs allow messages to be color coded.

Messages when the production line is meeting its pre-set goals, are shown in Green. They automatically turn yellow when the Actual parameter is below the set goal. Thus, management can see it from a distance how the line is running and take corrective actions.

Very simple wiring. Universal Power input, 15 wire cable.

The EZPM has 15 plug-in connection terminals. Not all may be used. For a very basic set up you may need only 9 wires. Different cables are available from EZAutomation.

Up to six inputs and two outputs. Dry contacts or proximity sensors.

The EZPM has six inputs for Production Count, Quality/Reject count, Reset at beginning of Shift, Pause/Restart for breaks or extended downtime, Data Log command and Count Alert Reset. These could be contact closures or solid state inputs. All inputs have a contact de-bounce circuit to eliminate false count. Two 5 Amp NO contacts are provided if you want to set up some audible alerts or any other action.

Communicates to a Lap top over WiFi up to 50 ft. away.

The EZPM will typically be mounted 10-20 ft. away from the operators on the line. For set-up and data monitoring on a computer, EZPM has a built-in Wifi that can be read from 50 ft. away eliminating the need to have a cable run for RS232 connection, but if a longer distance is needed to connect to a computer, three terminals are available to do this wiring. In such case an 18 wiring cable will be needed.

Patent pending smart logic to minimize tampering with the monitor and provide the most accurate information on plant productivity and quality.

The EZPM has unique patent pending logic to defeat any attempts to mislead the Production Monitor and display and/or record false data. It is not guaranteed to eliminate all miscounts but there is significant protection added to increase accuracy. You enter your own timing parameters during initial set up of the EZPM for a particular production line.

Real Time Clock and Data Logging for deeper analysis of production operations

The Most advanced model with Data Logging, has a Real Time Clock and a data logging feature. Production Supervisor/Manager should press the Data Log button as an input to the EZPM and it will record production and quality data for the day and append it its history file. History file can save data for over a year.

How to install and wire the EZ Production Monitor and How to set Production Parameters?

First thing you have to decide is where to mount the EZPM for visibility to operators, supervisors and managers. It comes with 2 brackets for mounting or it can be hung from a low ceiling.

Next you have to choose the right input sensors for production count input and quality/reject input. Sensor selection is extremely important. A contact closure or proximity sensor needs to be activated for count inputs. EZ Automation offers a whole line of proximity sensors that can be used. Starter kit already includes 30mm proximity sensor with a 1" sensing range. The sensors should be mounted away from the line operators. Additionally as some start and stop and reset buttons are needed, you'll have to build a small control panel with limited access to plant personnel. Anywhere from 9-15 wires in a cable will need to be connected between the EZPM and control panel. You can use your own cable or buy one from EZAutomation depending on number of wires and length.

As all EZPM's come with a built-in wifi, all you have to do is bring a laptop within 50 ft. of the Production Monitor and connect it to the Monitor. Free simple user friendly software is available from EZ Automation website. You will be entering the 5 parameters described earlier, additionally you would need to enter some timing parameters for the tamper proof logic, like min. time between count inputs, min. and max. duration of the count input. Your user interface will also display how the line is running. Count alert will activate if your production count input is grossly out of range from the parameters you set for your production line. Management intervention will be needed in case of count alert.

Extended Tech/Application support is available by writing to ezpm@ezautomation.net or calling 1-877-774-3279

Simplest User Interface

Enter 5 parameters:

- Part Number

- Shift Hours

- Goal per Hour

- Productivity Limit %

- Quality Limit %

The EZPM Does the Rest! Manager and Employees know in realtime how they are doing!! Displays on Marquee visible to 100 feet and also on computer/laptop 50 feet away