EZ7 HMI Features & Benefits

Innovative High-End Features

- Removable Front panel NEMA 4/4X: No cut-out, only HDMI cable through a 3/4" hole

- Front panel can be mounted 3 ft. away form the backend for greater flexibility using a special 3 ft. HDMI cable

- Patented HMI on-line edit, No downtime

- Only HMI that can still talk to AB’s DH+

- Upload HMI program from USB without software and cable

- Best looking objects and animation with 65K colors.

- On-Screen Recipe Edit.

- Every model Fully Loaded, No “R” Reduced Features models.

- Remote Monitoring and Control, Smart phones & Ethernet.

- Communicate to all PLCs, including DH+ & Ethernet IP.

- Dual PLC Drivers with automatic tag conversion.

- Mfr. cost reduction & IP protection for qualified customers.

- Most Rugged 0.090” thick anti-glare touch screen.

- Unique Visibility tag for best screen space utilization.

- Unicode for multiple languages.

- Easiest Programming Software, design time in hrs not days.

- Full Project simulation on your PC. Custom start-up screen.

- “C level” scripting and logic expressions.

- Data-logging, Recipes, Emails, USBs. Free Chart recorder.

- Most advanced Alarm management and logging.

- Pass-through programming for all PLCs.

EZ7 Human Machine Interface (HMI) Features & Benefits

EZ 7 Series, No cutouts, easily change displays, No rewiring.

New EZTouch EZ7 Series has another exceptionally innovative feature. It has a detachable front. First, the components that are most subject to wear and tear in an HMI are the touch screen and the LCD display. EZ7 allows the Front module (housed in a NEMA 4X metal housing) to be detached easily by unplugging an HDMI cable. This allows a field upgrade of display size for minimal cost. A 7” EZ7 can be replaced with a 12” EZ7. Our software also auto-detects the new display size and re-sizes objects to fit, no additional setup is required. All you do is connect the HDMI cable to the new display of any size.

The Front panel of EZ7 can also be mounted 3 ft. away from back panel using a special 3 foot cable (EZ7-CBL-HDMI3) needs to be ordered separately. This allows the control designer to have the back panel mounted on a different side of HMI enclosure or control cabinet for greater flexibility.

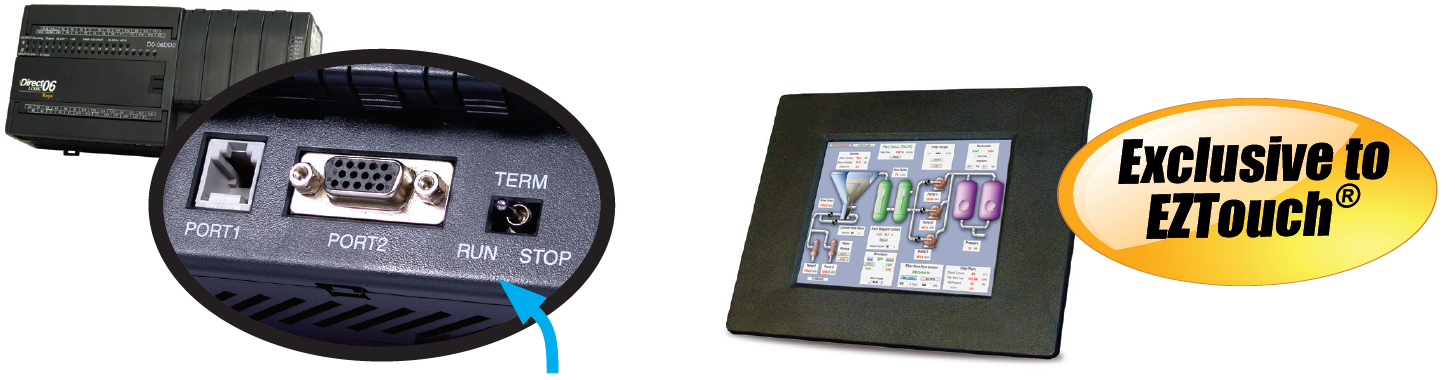

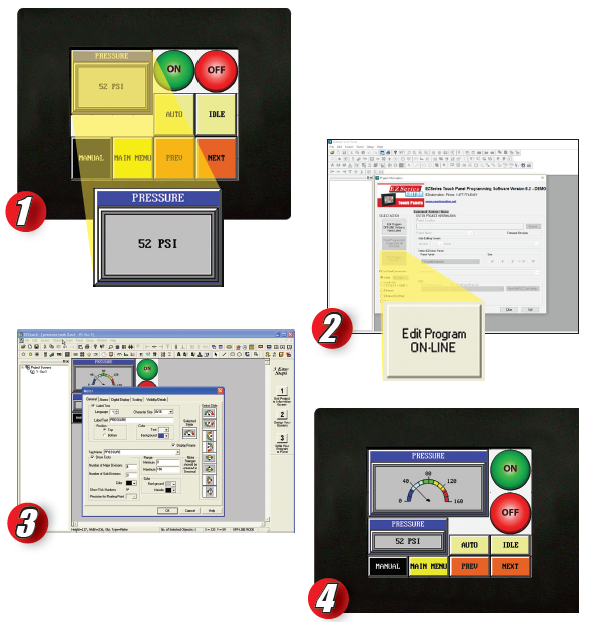

Patented HMI on-line edit, No downtime.

All HMIs except for EZtouch, require the machine or process to be shut down to make a change in the HMI program. While a new program is being uploaded to the HMI, it is non-functional and hence the machine can’t be allowed to operate during this time. Every time the HMI program is edited, there is machine down time of typically an hour. All EZTouch series HMIs have a patented on-line edit exceptionally innovative feature that allows the HMI program to be edited without the machine missing a beat.

In a recent study, more than 2/3rds of control

engineers, stated that after the HMI is

installed in a machine or process, the plant user,

system integrator, or OEM requests

some change in the screen design at least 10

times in the first 90 days following installation.

Even if you were able to make the change in

half-an-hour, machine/process will be down

by 0.5 hr. each time change is made. Taking

downtime at even a low cost of $1000/hr.,

the patented unique HMI online feature in all

EZTouch HMIs, saves you at least $5000 in just

first 3 months of operation.

400 NITs, 75K Hrs @ 55°C

When evaluating HMIs for you Machine or Application you should look at the overall cost of ownership. EZTouch displays all have durable LED backlight rated at 75K Hrs while operating at 55°C as compared to ost of our competition's 50k Hrs at 25°C. In addition, EZTouch displays have a higher brightness of 400 NITs as compared to 230 to 250 NITs from others. In short, EZTouch HMIs last twice as long. **Note: 12" model is specified at 300 NITs 50K Hrs @50° C

Tiny EZminiWifi installed on the HMI allows Laptop to program HMI from 50 ft. away.

This tiny little module that plugs into one of the serial ports in the HMI (we recommend installing on every HMI) allows a programmer to connect his/her laptop to the HMI without a cable. So many times, it is not so easy to reach the Operator console to connect the programming cable to the HMI. Combination of our patented On-Line Edit feature and EZminiWifi becomes an exceptionally innovative solution to making changes on HMI screens without having to open up the control cabinet and connect the Programming cable.

Only HMI that can still talk to AB’s DH+

Allen Bradley/Rockwell is no longer supporting its DH+ protocol originated in 1980’s. Whereas there are over one million nodes in manufacturing plants all over the world on PLC2, PLC5, SLC 500, Control Logix, Compact Logix and Micro Logix PLCs, there is no other HMI on the market that still supports the DH+ protocol (except for 7"). It is because of EZTouch HMIs that these plants do not have to change their networks to Ethernet I/P, saving them hundreds of thousands of dollars.

Dual PLC Drivers with automatic tag conversion.

All EZTouch HMIs now have the capability to simultaneously talk to two PLC networks. For example, Ethernet I/P on one side and Modbus RTU on the other side. Tags are automatically converted. This allows the two networks to communicate to each other through EZTouch.

Best looking objects and animation with 65K colors.

EZTouch HMIs have the best looking objects simulating real life panel actuators and indicators. And the animation of process is great. All EZTouch HMIs except the EZTouch Original now have 65K colors.

Most Rugged 0.090” thick anti-glare touch screen.

All EZTouch HMIs except the 12” model have an extremely rugged customized touch screen that is 0.090” thick as compared to paper thin touch screens used in our competitor’s products, increasing the durability of the EZTouch touch screen.

Mfr. cost reduction & IP protection for qualified customers.

EZAutomation has an extremely innovative service for its qualified customers. Many OEMs and System Integrators want to protect their intellectual property incorporated into their HMI. Since you are buying directly from our factory, for a certain minimum volume per month and a service fee, we can load your program and do a brief quality test of the HMI prior to shipping. This service cuts down your manufacturing cost of programming each unit prior to installation on the machine. This includes giving your product a unique part number of your choice to protect your investment in the purchase of your HMI by any third party. Call the Factory to find out the cost of this service per unit and other details.

Unicode for multiple languages.

All EZTouch HMIs have a Unicode feature for multiple languages, that is each Object can be displayed in different languages. This allows every operator of the HMI to be able to communicate to it in the language of his or her choice.

Easiest Programming Software, design time in hrs not days.

There is a reason why our company is called EZAutomation and our HMI is called EZTouch. We make it so easy to learn our programming language that no user, hundreds of thousands so far, thank you, ever had to attend any class to learn the programming. Most of our competitor’s products, like from Rockwell, Siemens, Mitsubishi, Unitronics, Schneider, Maple and others require a 3-5 day class to learn how to program their products. Our programming language is so intuitive and so simple that the design time for any screen and the entire project is reduced to hours instead of days.

Full Project simulation on your PC.

EZTouch programming software allows you to preview and test your entire project by our Project simulation feature on your PC itself before loading it up in your EZTouch. It’s a great time saver for programmers.

“C level” scripting and logic expressions.

This unique feature in all EZTouch products off loads a very substantial burden on the PLC and reduces PLC scan time, number of rungs, and size of memory, as these calculations can be done essentially off-line in HMI.

Data-logging, Recipes, Emails, USBs. Free Chart recorder.

EZTouch EZ3 can store HMI/PLC data on EZ3s USB or micro SD card and remotely retrive this data real-time over Internet using AVG File Manager. The USB drive or the micro SD serves as a free chart recoder saving the cost of an external chart recorder costing hundereds of thousands of dollars.

Most advanced Alarm management and logging.

*New Feature: EZTouch now provides an Alarm database, Alarm preview, Alarm history, Alarm count, Alarm protection and a special feature to send Alarm directly to EZMarquee. It also allows for the EZtouch HMI to email or text alarm messages.

Plantview Capability

All EZTouch EZ7 HMIs in a plant or multiple plants, have the capability of getting monitored by using EZPlantview software allowing all critical parameters to be collected and displayed in the individual EZ7 HMI which can be viewed on one or multiple large screens in a control room.

On-Screen Recipe Edit.

All EZTouch HMIs feature an on-screen recipe edit where you can edit the recipe on the HMI itself without needing to connect to a laptop with programming software.

Remote Monitoring and Control, Smart phones & Ethernet.

All EZTouch HMIs have a remote monitoring and control feature where you can monitor and control the functionality of an HMI remotely via a Smart phone with iOS or Android OS. RMC can also be done over Ethernet connection in all EZTouch HMIs.

Communicate to all PLCs, including DH+ & Ethernet IP.

EZTouch HMIs have the highest connectivity to a PLC with serial protocols, Ethernet protocols such as Ethernet IP, Modbus TCP/IP, GE SRTP, Siemens ISO, K-sequence and of course the EZ Protocol, as well as DH+. Serial protocols cover 98+% of all PLCs in the market.

Unique Visibility tag for best screen space utilization.

EZTouch HMis have an extremely innovative Visibility tag on all objects. Object appears on the screen only if the visibility tag is true. Along with EZTouch’s feature of overlapping objects, visibility tag is a great space saver on the screen.

Pass-through programming for all PLCs.

All EZTouch HMIs allow pass-through programming of any device connected to the HMI, whether it is a PLC, PAC or a Drive. PLC Programming software of any make, for example Rockwell can pass through the same programming port as the EZTouch programming software making it very convenient to program the whole control system through just one port/connection.

Patented HMI on-line edit, No Machine Shutdown, No downtime!

You wouldn’t buy a PLC today

if it didn’t have On-Line Edit...

...So why should you have to buy a Touch

Panel without On-Line Programming?

Only the EZTouch® has On-Line Programming

1. After a machine upgrade including a new PLC and Operator Interface, our System Integrator asked the Machine Operator what he would like to see better yet. The Operator said the new “computer” was great with all

the colors but he missed the old pressure gauge.

2. Our System Integrator immediately pulled out his notebook computer, hooked it up to the Touch panel, launched his programming software and put it in On-Line mode.

3. And then, right in front of the operator’s eyes, moved the other objects on the screen and put an Analog Meter exactly to the operator’s color taste, without ever having to shut down the machine.

4. All this took less than 2 minutes.

Operator: “Now that is nice!”

Let’s get these on all the machines.”

PLC Communications and Drivers

The EZSeries HMI Touchpanels communicate to more PLCs and Networks than any other HMI. Allen-Bradley panels talk to mostly AB PLCs, Siemens panels talk to their PLCs, Mitsubishi HMIs communicate mostly to their PLCs and so on.

A vast majority of North American Plants still have AB's Data Highway Plus (DH+) networks in place.

Industrial Ethernet is fast becoming the communication platform for an increasing number of plants all over the world. But Ethernet without the proper supporting protocol (software driver) is like having a great vehicle without tires. Not so with EZAutomation, our EZ7 EZTouch HMIs can communicate to all major ethernet networks including but not limited to:

- Allen-Bradley Ethernet I/P to Controllogix and Compactlogix

- DF1 protocol over Ethernet for Micrologix & SLC 500 series PLC's

- Siemens Ethernet ISO over TCP/IP

- Modbus TCP/IP

- SRTP for GE networks

No other Touchpanel HMI manufacturer other than EZAutomation and Uticor can communicate over Data Highway Plus (DH+)

This is a great feature for OEMs and System Integrators to consider, when selecting a Touchpanel HMI to be their standard HMI.

Hardware Drivers Supported on EZ7Touch HMI:

• DH+

EZ7 EZTouch Supported Drivers: |

|

Allen Bradley: Automation Direct: ABB: (COMLI Driver) All Motion: (EZ Stepper) Animatics: (Smart Motor) Applied Motion: (SCL series) Aromat: (Mewtocol) AVG / EZAutomation: Baldor: (Host Comms) Bristol Babcock: BSAP Native (serial) Control Techniques: Unidrive 2-wire, 4-wire (binary) |

Control Technology Corp (CTC): CTC 2600, 2700 and 5100 (CTC Binary) IDEC: Computer Link Keyence: (CV 5000) Mitsubishi: Modicon / Schneider: Omron: Host Link Adaptor Siemens: Texas Instruments (TI): Square D: Yaskawa: |

Remote capability over PC, Tablet or Smart Phone (Apple iOS and Google Android)

If you need assistance, be sure to visit the RMC Support page.

EZ RMC™ Remote HMI is an application designed for your mobile devices on both iOS and Android platforms, for the monitoring and control of your EZTouch HMIs from EZAutomation.net. Enjoy direct access to your EZTouch HMI from anywhere at the tips of your fingers, on your phone or tablet. The EZ RMC™ Remote HMI is available on both the iTunes App Store as well as the Google Play store.

EZ RMC™ Remote HMI is an application designed for your mobile devices on both iOS and Android platforms, for the monitoring and control of your EZTouch HMIs from EZAutomation.net. Enjoy direct access to your EZTouch HMI from anywhere at the tips of your fingers, on your phone or tablet. The EZ RMC™ Remote HMI is available on both the iTunes App Store as well as the Google Play store.

Features:

- Realtime View and Control of your EZTouch HMI panel

- "Pinch" style zoom for more in-depth view of your HMI project

- Save screenshots directly from the App

- Multiple user accounts can be configured for each panel project, with multiple levels of security, including either only Viewing ability, or both Viewing and Control

- Record your most used panels in your Favorites for quick access, and designate one HMI for direct access by default when the App is opened

Compatibility:

- iOS App works with all iOS devices (iPad, iPhone, iPod Touch) running iOS version 6 or later

- Android App works with devices running OS version 4.0.3 - Ice Cream Sandwich or later